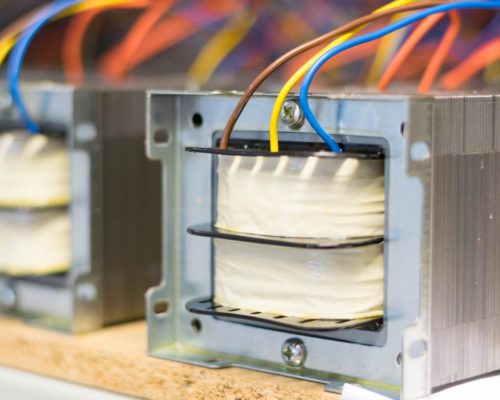

Custom Design & R&D

custom magnetics to customer’s specifications

CUSTOM DESIGN SERVICES

Carnhill Group’s OEM customers often require magnetics which meet their own requirements and which are not part of the existing product line. If you do not see the audio transformer or inductor you need already listed on our web site, please contact us to discuss your needs.

There is a good chance that we have already engineered it or something close to it, and if not we welcome the chance to develop new and useful designs. Our online catalogue represents only a small fraction of what we manufacture. If you do not see it here, ask. We develop new ones all of the time to meet customers’ requirements.

DESIGN AND DEVELOPMENT

Carnhill Group can support the customer, from the initial concept of the product through the product design, prototype manufacture and production engineering. We offer technical and practical support, as well as being able to supply customers with a rapid sampling service.

Carnhill Group aim to use our experience and skill to combine excellent engineering integrity with commercial considerations. This is to provide a product that suits manufacture and meets the application’s requirements. Our designers work closely with our customers to ensure the optimum designs are achieved to produce non-standard wound assemblies for special applications. Familiarity with a wide range of materials suitable for operation at different temperatures and in different environments allow components to be designed for a wide range of applications.

Although a variety of non-standard assemblies have been produced, the expertise is often applied to the construction and winding techniques for more standard type assemblies where special performance or test parameters have been specified.

ENGINEERING

At Carnhill Group, our production is supported by the in-house mechanical engineering workshop. The Carnhill Group workshop is able to produce winding mandrels, production jigs and fixtures specifically suited to the manufacture of individual coil styles.

EXPERIENCE

Carnhill Group have an experienced workforce, with the manual skills to carry out the hand winding of intricate coils. This allows the supply of unusual and complicated products that are not suitable for machine manufacture.